Adding visual details to your architectural design is key to drawing in curbside appeal. As the cornerstone of our architectural range, a perforated metal sheet by Locker is developed in-house and offers precision-made features to add the spark you're looking for in a façade.

We rely on PicPerf® for all of our perforated metal image design work. While you may have seen it mentioned in Architecture and Design or one of our end-of-year Lookbooks, this article will highlight what the process is, how it works and why we use it.

Customised perforated metal

PicPerf® is a digital imaging processing program made specifically for perforating metals. It takes positive or inverted images and converts them into our perforated metal program. The software uses the holes in the sheet metal and background colour to create a textured 3D effect. It can be scaled for large or small spaces depending on the needs of the project.

Background lighting and viewing distance are taken into consideration as we design the image for the program. For example, a positive image will rely on a dark background, where an inverted image needs some sort of background light either natural or synthetic. The optimal viewing distance will depend on the size of the holes used for the façade.

We may also need to use a coated metal either in light or dark colours to achieve the correct contrast.

Additionally, the thickness of the perforated sheet metal is determined by how large the façade is and the size of the holes necessary for the project. The detail required for the image is another factor when determining metal thickness.

We highly recommend using aluminium for exterior façade, but we also offer stainless steel and mild steel. Aluminium has incredible resistance to corrosion and will be able to maintain the original design for longer without much need for maintenance or short-term replacement. Steel, however, while only suitable for two-tone images, is an excellent option for indoor applications.

Benefits of using custom perforated metal

If you're looking for architectural uniqueness, perforated metal façades or partitions offer the ideal solution. Perforated panels are used for protection from the sun, wind, air filtration, sound control and separation. A customised design provides visual interest and adds aesthetic value to a space.

A façade or partition can even provide a level of opaqueness to a space as you can see through either side of the panel. A customised partition is an excellent option for spaces such as a bus stop or an airport where some sun protection is necessary while waiting for transportation. The pattern you choose will also provide visual relief in an otherwise dull environment.

Perforated metal design and production steps

Locker uses PicPerf® to customise a perforated metal sheet based on your needs. All it takes is a few easy steps:

- Provide the image you want to be used for the metal panel. This will include the folds and bolts necessary.

- We will input the image into PicPerf® where we will determine if the image will be split into multiple panels, how large or small the holes will be and the thickness of the sheet itself.

- Once the terms are agreed upon, we will send the completed image to our perforation machine to punch the image into the sheet.

- The surface will then be treated, powder-coated or anodised for the desired finish.

We will include bolt holes into the production to ensure the panels are ready for installation. The bolt holes are incorporated into the design of the façade or partition.

If you're looking for a unique design and a façade or partition that will add visual appeal to your next project without compromising the integrity of the building, contact us for more information.

Industrial stair treads can prevent slips and falls.

Industrial stair treads can prevent slips and falls.

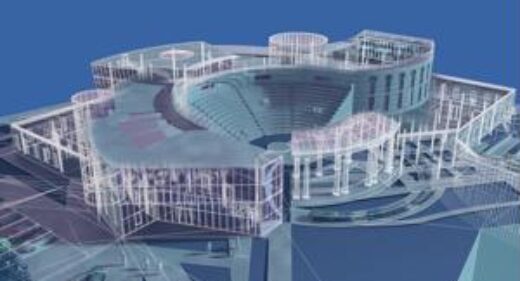

On-time and within scope, Locker’s Aurora system helped pull together different teams into the same timeline.

On-time and within scope, Locker’s Aurora system helped pull together different teams into the same timeline.

Teamwork, dedication and vision brought this façade to where it stands today.

Teamwork, dedication and vision brought this façade to where it stands today. With minimal direct sunlight, vehicles can stay cool in the summer.

With minimal direct sunlight, vehicles can stay cool in the summer.

Expanded mesh can be an excellent source of decorative inspiration.

Expanded mesh can be an excellent source of decorative inspiration.