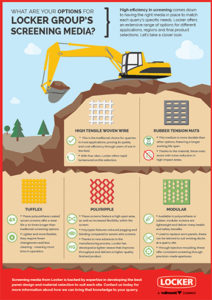

Poly

Modular

Locker Group Mining offers a range of polyurethane screening alternatives;

- injection moulded polyurethane panels, in a range of sizes, primarily 1ft x 1ft or 2 ft x 1 ft or 300mm square configurations,

- open cast polyurethane screen mats

- cross tensioned mats

- Range of fixing systems

- Trommel screen panels

Like for like replacement panels are available, manufactured to order.

In addition, Locker Group Mining offers a fully customised design service. Our technical experts will analyse every detail of your screen setup to assess the correct aperture, fixing system and polyurethane mixture to maximise the screening efficiency of your site, while maintaining the wear life between shutdowns.

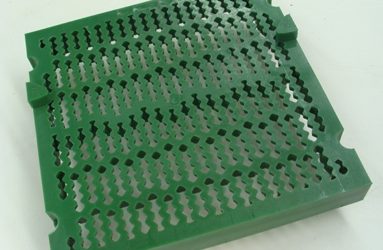

The injection moulded process ensures accurate openings and consistent construction in every poly modular panel.

The technology allows for surface features, such as cross dams and rider bars, to be incorporated into the original panel construction, rather than attached later. This process allows for stronger, more durable panels.

The benefits of the injection moulded polyurethane modular panels include the ability to change out only sections of the screen deck, maximising wear life, and minimising any OH&S risks due to their light weight and manageable size.

Locker Group will custom design aperture profile and size to suit individual customer requirements, taking into account feed size and rate, moisture content and final product requirements.

Various openings can be incorporated into the same deck design, including feed impact zones. The flexibility of a modular system allows the screen to include a combination of different apertures, tapered openings, and different material in panels, to suit the individual site requirements.