Plastic grating versus metal grating: which to use

Grating is a core component of many industrial facilities. This dependable flooring can do it all. It supports workers and the equipment and supplies they carry every day while standing up to heavy loads, high heat, chemical spills and other concerns.

Grating is easily cleaned and relatively simple to install. It has a low cost compared to other types of industrial flooring and doesn't require significant, regular maintenance. It promotes air circulation and, crucially, provides a safe, slip resistant and reliable surface for employees as they go about their duties.

Plastic grating and metal grating are the two major types of industrial grating in common use today. Understanding the differences between them and the best applications for each will allow you to make an informed decision that will address the needs in your facility.

What is plastic grating? When should I use it?

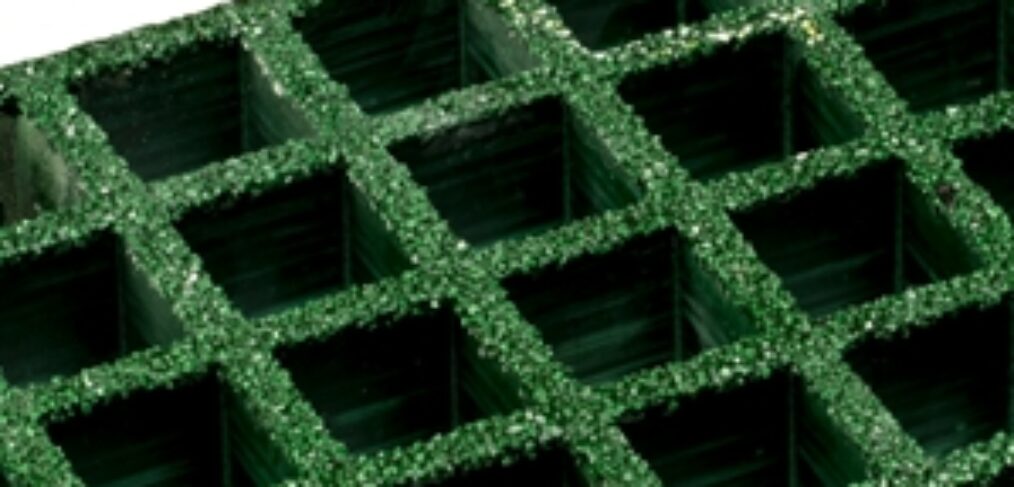

Plastic grating is a more general term for fibre reinforced plastic grating, often referred to as FRP grating. This type of industrial flooring is composed of glass fibres, which have a high degree of resistance to tension and compression, with a durable plastic that can stand up to the demands of modern facilities.

There are a number of benefits when it comes to FRP. Load-bearing capacity, the foundational element of any type of flooring, is important to point out. Because FRP is generally produced in a single piece with a square grid pattern, it allows for efficient weight distribution. That's true on the grating itself as well as the support structure it's connected to. When employees have to carry heavy equipment or large loads of raw materials or finished products across an elevated surface – or any other one where grating is preferred – FRP can capably support their work.

The overall safety of the work surface is improved by a few other key attributes:

- Chemical resistance: Caustic chemicals and related concerns are a fact of life for businesses involved in heavy manufacturing and many other segments of the economy. FRP grating offers a high degree of resistance to corrosion caused by many industrial chemicals. Workers, safety supervisors and managers won't have to worry about hazardous corrosion that could lead to workplace injuries. From a structural integrity perspective, it's a safer choice in many cases.

- Slip and fall protection: While many of the benefits of FRP grating come from the advanced processes and techniques used to fabricate it, a simple addition offers standout protection against frequent sources of workplace injuries: slips and falls. When a coarse grit is added to the top surface of the grating, staff can more safely move across it. In situations where the grit may cause issues, a smooth surface can also be produced.

- Lack of sparking, conductivity and magnetism: Because FRP doesn't contain metal, it won't produce sparks if metal tools or other objects fall onto it or are dragged across it. Similarly, it won't carry an electrical current in the same fashion as metal grating. Additionally, it doesn't have any magnetic field to speak of – making it a preferred choice in some applications.

When should you use FRP grating? Considering its many attributes, it has plenty of applications. But it can perform best in situations where corrosion resistance is a must, slips and falls are a major concern and when metal grating could introduce additional possible hazards in the workplace.

What is metal grating? When should I use it?

Metal grating is an umbrella term that can apply to many grating types, including:

These common types of industrial floor gratings offer an effective combination of support, strength and security. There are also more configurations available for metal grating than for FRP. With steel and aluminium options, your company can select from a variety of top surfaces that promote safe travel now and for years into the future. Different surfaces can be used in areas with especially high risk for or notably negative consequences from slipping and falling, such as on sloping walkways and at high elevations.

Stainless steel grating's major benefit is strong resistance to rust and corrosion. Whether caused by chemicals, ambient moisture or a mix of both, stainless steel doesn't easily rust or corrode. While metal grating has many useful applications, this is one area where the stainless steel variety truly shines.

Aluminium grating also offers strong resistance to moisture, helping to substantially slow the appearance and spread of rust. Anodised aluminium, meanwhile, has enhanced durability thanks to a process that binds the substrate metal with a layer of aluminium oxide. This improves durability. Notably, anodised aluminium can last between 20-50 years, depending on the specifics of its production and its application. Overall, aluminium's value comes from its light weight and its pleasing appearance. In applications where these factors are central to the success of a project, aluminium grating is a strong choice.

Moving forward with your next project

Your organisation understands the unique demands of your construction or renovation project better than anyone else. By developing a detailed list of the intended uses of grating in a specific area as well as the potential hazards that could exist, you can develop a profile that will help guide your decision-making. From there, the next step is finding a reliable and experienced partner that can fabricate and provide the type of industrial floor grating best suited to your project.

Webforge offers a range of industrial gratings, both in premade panels that address the needs of many projects as well as custom-fabricated panels that align with more unique applications. With more than 75 years of experience in producing industrial flooring and many of the products associated with it, we have a strong understanding of the entire process from start to finish.

To learn more, get in touch with us today.