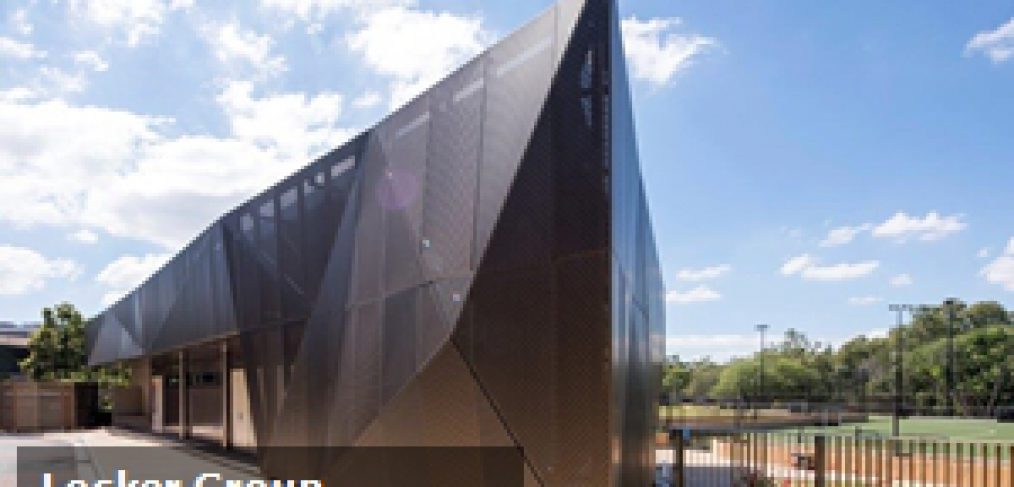

At Locker Group we make no secret of our love for perforated metal. We have over 60 years experience in manufacturing this bold and versatile product, and know how much it can add to both the interior and exterior of architectural projects.

However, you don't have to just take our word for it. This article gives 4 recent examples of perforated metal in architectural action from across the globe. Prepare to be amazed:

1. The Miami Museum Garage

Any building constructed in Miami's Design District will have stiff competition when it comes to standing out from the crowd – this area is known for innovative design, art and architecture.

We'll let you judge for yourself, but we'd say the Miami Museum Garage does a pretty good job. The facade is inspired by ant colonies, with the structure representing a similar hive of activity. Public areas such as a playground, a garden and an art space are selectively shown, with the rest of the building disappearing behind an epic perforated metal screen.

This is a perfect example of why perforated metal is excellent for use in facades. Not only is it visually striking, this building makes use the material's natural capacity for sun and wind shelter while also permitting great air and light filtration.

2. Yokohama nursery

There are many aspects of the Yokohama nursery that make it a great piece of architecture. From the warm interior feeling created by the plywood boards to the windows designed to resemble traditional dwellings in the area, every aspect is well thought through and well executed.

However, the aspect of this building that really stands out to us is the perforated metal facade. Not only does it stand out from the white structures on either side of the nursery, the perforation pattern has been cleverly arranged to resemble the constellations of a galaxy. Now these kids get to literally play among the stars!

3. Salesforce Transit Center

Opened to the public on the 11th of August 2018, the Salesforce Transit Center is a truly iconic addition to the city of San Francisco. The building, which was 17 years in the making and will serve as a central transport hub for the city, is said to be inspired by nature as well as art and math.

The design features a jaw-dropping 3,992 perforated white aluminium panels.

The design features a jaw-dropping 3,992 perforated white aluminium panels, decorated with an intricate geometrical pattern designed by mathematician and physicist Sir Roger Penrose.

For those who want to take things a step further, Locker Group offers a Pic Perf range of facades where images can be precisely perforated into the metal sheet, creating a truly unique and eye-catching result.This structure really shows off the artistic capabilities of perforated metal. One of the features of this product that makes it so engaging for architects is the fact that there is an almost limitless variety of patterns and shapes that can be punched in.

4. The Vancouver 'Tree House'

Here's one for the future.

The slopes of West Vancouver will soon be graced with the presence of a 12 story condo building, which at this point is being called the 'Tree House'.

The perforated metal will be used in the soffits of individual units which will cantilever from the main structure.

The facade will feature a range of materials including dark painted metal, exposed concrete and, you guessed it, perforated metal. Here, perforated metal will be used in the soffits of individual units which will cantilever from the main structure.

The material was chosen for this project for reasons similar to the Miami Museum Garage – namely its ability to provide visual contrast and shade. The 'Tree House' is designed to blend into its surroundings, and the capacity that perforated metal has for establishing natural feeling light flow will be of great use in fulfilling this aim.

We hope this article goes someway to showing you the amazing potential that perforated metal has for use in architecture. Each of these projects use the material in different ways, and architects need to be able to count on suppliers to deliver products on schedule, and to their exact specifications. Locker Group prides itself on working closely with our clients to ensure that high quality and reliable deliverables.