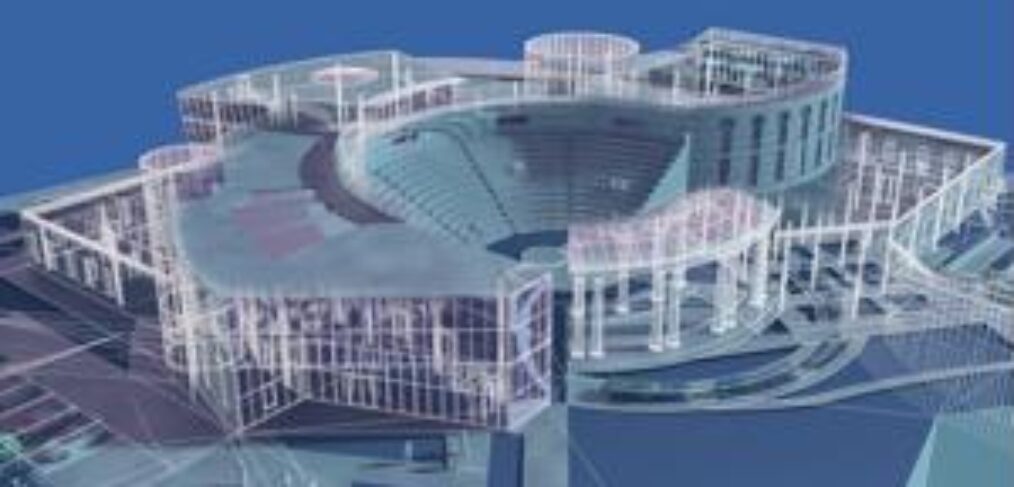

Architectural design can take on many forms either to stand out from or to blend in with the surrounding geography. Adding colour, texture and shapes from the surrounding environment of a new building wall façade can add a more harmonious design to the area. This article will explore why you may want to incorporate your next building into the landscape rather than giving it a distinctive design.

Why blend your architectural façades?

Building façades offer benefits to buildings such as shielding them from wind, protecting them from the sun, facilitating passive cooling or providing opportunities for natural ventilation. The architectural design could incorporate features that absorb flood waters or improve aesthetics as well. All of these elements are in response to the surrounding environment of the building and the intent of the structure itself.

A blended architectural façade design offers a more harmonious quality to a landscape. Instead of constructing a structure that is meant to stand out, a balanced design causes less impact on the surrounding area.

A 2018 journal by Nazire Papatya highlights the importance of sustainable building design, citing that using the landscape as a base for your drawings could improve its energy efficiency and synchronicity with the environment. This could not only mean using perforated metal façades but pulling in colours of the local plants and ground to deepen the visual impact.

Architectural methods to implement this design

While Papatya's dissertation on architecture design primarily focuses on using plant life to manage sustainable structures, there are man-made options you can use as well. The best way to blend a new building with the landscape is to first survey the land. Understand how the space slopes and consider the likelihood of heavy rain, wind or sunshine at certain times of the year or day. Then take in the colours you might use that will coordinate with the landscape.

Generally, a building is meant to communicate a sense of comfort and safety from the elements. This doesn't mean you need to build a fortress made out of titanium metal, but consider a façade that not only protects and provides durability but compliments the area around it as well as the function within.

Perforated metal, expanded metal or woven wire could serve these purposes perfectly as they are not only versatile but can coordinate with the landscape via a coloured coating. The material you choose should also take into consideration how it will fade over time. Choosing a metal that is corrosion resistant like aluminium can add improved longevity to the structure while maintaining its original intent.

A traditional or contemporary design could determine how you incorporate different materials as well. An exterior wall with floor-to-ceiling windows, or ground-to-roof perforated metal could meet your needs for either a modern or traditional design — it's all a matter of how you choose to incorporate colours and textures of the elements around the building to inspire you.

Locker offers an architectural design solution

From ideation to construction, Locker offers the façade solution you need. We are the leader in the perforated sheet metal market, offering a range of woven and welded metal mesh for a full-service design to product solution. We specialise in mild steel, galvanised steel, brass and stainless steel metal material available for your needs, both made-to-order or custom designed.

Adding a visual spark or integrating your design with the landscape is easy with Locker's decades of experience. We can ensure you get both a product that is perfect for the needs of the building as well as your architectural vision.

To get started or to learn more about our product solutions, contact us today.

On-time and within scope, Locker’s Aurora system helped pull together different teams into the same timeline.

On-time and within scope, Locker’s Aurora system helped pull together different teams into the same timeline. The three-storey car park façade is a statement point for the district.

The three-storey car park façade is a statement point for the district.

Teamwork, dedication and vision brought this façade to where it stands today.

Teamwork, dedication and vision brought this façade to where it stands today. With minimal direct sunlight, vehicles can stay cool in the summer.

With minimal direct sunlight, vehicles can stay cool in the summer.

Expanded mesh can be an excellent source of decorative inspiration.

Expanded mesh can be an excellent source of decorative inspiration.

Elevate your space with metal sound-absorbing paneling.

Elevate your space with metal sound-absorbing paneling.