Metal screens have plenty of practical applications in residential and commercial structures. These screens can serve as a decoration, a functional component of the building or fulfil both roles at the same time.

Whether fabricated as a standard size panel or customised for unique projects, metal screens can address a wide range of widespread aesthetic and practical needs. There are also some less common applications in which these screens can be just as useful. Let's look at a few of them:

1. Branding and identification

Decorative metal screens may not be the first thing that comes to mind when your business starts to consider opportunities around branding your building or helping visitors identify it. But improvements in the tools and processes used to create screens have led to a variety of options on this front.

Our Pic Perf screens offer the opportunity to faithfully reproduce many logos, images and abstract patterns with a high degree of accuracy. There are few limits when it comes to implementing a custom design on a Pic Perf screen. Whether you want to use a wordmark or an image that makes your building's purpose clear, you can work with our team of experts to craft a solution that aligns with your goals.

With the right design factors taken into account, Pic Perf can also offer many of the practical benefits of metal screens. That includes benefits like protection from direct sun exposure and maximised airflow.

2. Privacy and protection

The need for privacy exists in settings ranging from restaurants and shopping centres to apartment buildings and office blocks. The right degree of separation from the outside world doesn't always require locked doors and windowless rooms, however.

Privacy screens can provide a happy medium between a bunker-like atmosphere and total exposure to the outside world. They limit visibility without completely cutting off the rest of an office floor or commercial space, creating a sense of openness that takes the aesthetics of a given area into account. When paired with a glass partition, screens can provide an effective barrier in terms of both visibility and sound.

Using metal screens for privacy isn't limited to internal applications, either. Facilities like medical centres, schools and many others can utilise laser-cut screen options to create a sense of separation without eliminating access to sunlight or visibility into the local area.

3. Balustrades

A balustrade is made up of a railing that's held securely in place by a support rising from the ground. While vertical columns are the first thought for many when it comes to balustrades, there are many options for decoration as well as functional support. Perforated screens can add a unique element to what is often simply a functional part of a building. Adding ornamentation to a transitional space like a stairwell can make the experience of moving through them a little more enjoyable.

4. Regulating temperature and sunlight exposure

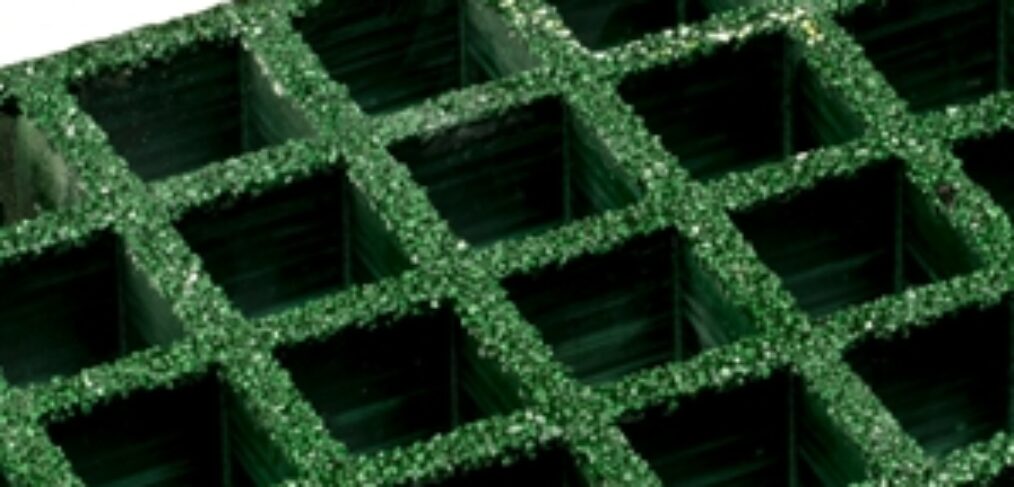

Modern architectural screens tend to have an impressive appearance, whether they're made of expanded metal mesh, woven wire or a number of other materials. This is often the first thing an employee, visitor or passer-by will notice as they approach a structure. However, it's far from the only reason to include a screen in your construction or renovation plan.

Screens have a core practical function when placed outside exterior windows or in interior spaces that face substantial exposure to sunlight. By filtering sunlight without completely blocking it, metal screens can help to regulate temperature and exposure to sunlight. While some people who visit or work in a building may never notice the practical benefits of a metal screen used in this fashion, they'll more than likely enjoy the result.

5. Roofing

You wouldn't use a metal screen to cover the top of a building, of course. But what about an outdoor space for staff to enjoy their breaks, or an open green included in part of an outdoor shopping centre?

Using screens as roof replacements can offer practical and aesthetic benefits. Laser cut, perforated and many other types of metal screens can limit sun exposure without eliminating it, providing an enjoyable mix of light and shade. Pairing metal screens with a central walkway or seating area that includes a traditional roof structure can help protect employees, customers and visitors from the elements when needed, while offering a unique space on days with nicer weather.

Getting started with your own unique plans for metal screens

Whether you want to use the most traditional metal screen possible or have a truly unique idea for a design or application, you need a trustworthy provider who can assist you throughout the process. To learn more about your many options for metal screens, get in touch with our team of experts today.